Recently, the 1500-ton per year dichlorodihydrosilane (DCS)-to-silane industrial plant, developed by Prof. Xuegang LI's team from the School of Chemistry and Chemical Engineering (SCCE) at Shanghai Jiao Tong University (SJTU), was completed and put into operation at Sichuan Yongxiang Energy Technology Co., Ltd., a subsidiary of Tongwei Co., Ltd.. This plant is the world's first industrial demonstration unit for the new DCS-to-silane process, with the complete technology package provided by Prof. LI's team.

Silane is the most important and widely used specialty gas in microelectronics and optoelectronics fields, extensively applied in semiconductor chips, display panels, and solar photovoltaics. Silicon-carbon composite materials, with silane as the silicon source precursor, are the most promising next-generation high-performance anode materials for lithium-ion batteries. Due to the high purity requirements of the product, significant technical challenges, and its extremely flammable and explosive nature, even low-grade products for energy-saving glass in China used to rely on imports.

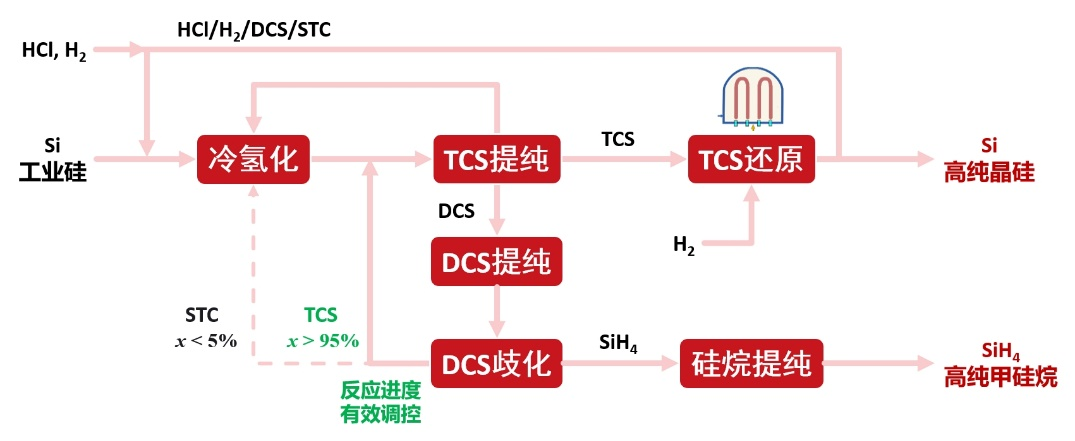

The traditional silane production process uses trichlorosilane (TCS) as a raw material, producing silane through a disproportionation reaction with silicon tetrachloride (STC) as a byproduct. This method is inefficient and energy-intensive. Prof. Xuegang LI 's team developed a new process that uses DCS, a byproduct from the hydrogenation and reduction sections of the modified Siemens process for polysilicon production, as the raw material. This new process employs a reactive distillation multifunctional reactor to produce silane.

Through extensive fundamental research and innovations in core processes and equipment, the team overcame the challenge of impurity removal from DCS, enhanced the DCS disproportionation reaction process, and effectively controlled the reaction progression. This made TCS an advantageous byproduct, with the selectivity of the final disproportionation byproduct STC being less than 5%. The byproduct TCS can be returned to the polysilicon section for polysilicon production, achieving a close integration of the silane process with the modified Siemens polysilicon process. Compared to the traditional TCS route, the new technology reduces fixed asset investment and unit product energy consumption by over 15% and 60%, respectively.

The photovoltaic sector is currently the largest consumer of silane. Tongwei Co., Ltd. is a global leader in PV product manufacturing, with a comprehensive PV new energy industry chain that includes upstream high-purity polysilicon production, midstream production of high-efficiency solar cells and modules, and downstream construction and operation of PV power plants. Its subsidiary, Yongxiang Co., Ltd., is the world's largest producer of high-purity polysilicon. The successful launch of this project will help the company enhance its profitability and promote the long-term healthy development of its PV industry chain.

Address:800 Dongchuan RD. Minhang District, Shanghai, China

PostCode:200240 Tel:021-54742893 E-mail:sjtuscce@sjtu.edu.cn

Copyright@ 2023. All rights reserved. Powered by SCCE ICP:2010917